NATIONAL INSTITUTE OF INDUSTRIAL ENGINEERING

PGDIE-42

Industrial Engineering

Assignment on Product Manufacture:-

Presented By: -

Amit Rana

Roll

NO. 108

Vaibhav Jijani

Roll No.99

PGDIE 42

Manufacturing of Spur Gear Using Powder Metallurgy

INTRODUCTION

Powder Metallurgy is a proven technology to produce high strength gears and tailored gear shapes for both automotive and industrial applications. Advances in powder production, compaction, and sintering combined with unique secondary processing methods have enabled overall part densities above 7.5 g/cm3. These techniques have proven successful in displacing many components from competing technologies in a variety of end user applications. The reason for P/M’s success is its ability to offer the design engineer the required mechanical properties with reduced component cost. At the present time, P/M is successful in many performance areas. Discussed here are three applications that expand the potential for P/M use in additional environments.

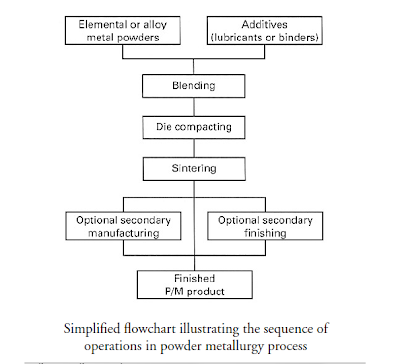

The powder metallurgy process generally consists of four basic steps:

(1) powder manufacture,

(2) powder blending,

(3) compacting,

(4) sintering.

Compacting is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure. Optional secondary processing often follows to obtain special properties or enhanced precision.

DESIGN OF SPUR GEAR

The spur gear is is simplest type of gear manufactured and

is generally used for transmission

of rotary motion between parallel shafts. The spur gear is the first

choice option for gears except when high speeds, loads, and

ratios direct towards other options. Other gear types may also be

preferred

to provide more silent low-vibration operation. A single spur gear is

generally selected to have

a ratio range of between 1:1 and 1:6 with a pitch line velocity up to

25 m/s. The spur gear has an operating

efficiency of 98-99%. The pinion is made from a harder material than

the wheel. A gear pair should

be selected to have the highest number of teeth consistent with a

suitable safety margin in strength and wear.

The minimum number of teeth on a gear with a normal pressure angle of 20

degrees is 18.

The preferred number of teeth are as follows

12 13 14 15 16 18 20 22 24 25 28 30 32 34 38 40 45 50 54 60The preferred number of teeth are as follows

64 70 72 75 80 84 90 96 100 120 140 150 180 200 220 250

The lines normal to the point of contact of the gears always intersects the centre line joining the gear

centres at one point called the pitch point. For each gear the circle passing through

the pitch point is called the pitch circle. The gear ratio is proportional to the diameters

of the two pitch circles. For metric gears (as adopted by most of the worlds

nations) the gear proportions are based on the module.

m = (Pitch Circle Diameter(mm)) / (Number of teeth on gear).

In the USA the module is not used and instead

the Diametric Pitch d pis used

d p = (Number of Teeth) / Diametrical Pitch (inches)

Profile of a standard

1mm module gear teeth for a gear with Infinite radius (Rack ).

Other module teeth profiles are directly proportion . e.g. 2mm module teeth are 2 x this profile

Other module teeth profiles are directly proportion . e.g. 2mm module teeth are 2 x this profile

Terminology - spur gears

- Diametral pitch (d p )- The number of teeth per one inch of pitch circle diameter.

- Module. (m)- The length, in mm, of the pitch circle diameter per tooth.

- Circular pitch (p)-The distance between adjacent teeth measured along the are at the pitch circle diameter

- Addendum ( h a )- The height of the tooth above the pitch circle diameter.

- Centre distance (a)- The distance between the axes of two gears in mesh.

- Circular tooth thickness (ctt)- The width of a tooth measured along the are at the pitch circle diameter.

- Dedendum ( h f )-The depth of the tooth below the pitch circle diameter.

- Outside diameter ( D o )- The outside diameter of the gear.

- Base Circle diameter ( D b ) - The diameter on which the involute teeth profile is based.

- Pitch circle dia ( p )-The diameter of the pitch circle.

- Pitch point- The point at which the pitch circle diameters of two gears in mesh coincide.

- Pitch to back- The distance on a rack between the pitch circle diameter line and the rear face of the rack.

- Pressure angle- The angle between the tooth profile at the pitch circle diameter

and a radial line passing through the same point.

- Whole depth.-The total depth of the space between adjacent teeth.

Mild steel is a poor material for gears as as it has poor

resistance to surface

loading. The carbon content for unhardened gears is generally

0.4%(min) with 0.55%(min)

carbon for the pinions. Dissimilar materials should be used for the

meshing gears - this particularly

applies to alloy steels. Alloy steels have superior fatigue properties

compared to

carbon steels for comparable strengths. For extremely high gear loading

case hardened

steels are used the surface hardening method employed should be such to

provide sufficient case depth for the final grinding process used.

| Material | Notes | applications |

| Ferrous metals | ||

| Cast Iron | Low Cost easy to machine with high damping | Large moderate power, commercial gears |

| Cast Steels | Low cost, reasonable strength | Power gears with medium rating to commercial quality |

| Plain-Carbon Steels | Good machining, can be heat treated | Power gears with medium rating to commercial/medium quality |

| Alloy Steels | Heat Treatable to provide highest strength and durability | Highest power requirement. For precision and high precisiont |

| Stainless Steels (Aust) | Good corrosion resistance. Non-magnetic | Corrosion resistance with low power ratings. Up to precision quality |

| Stainless Steels (Mart) | Hardenable, Reasonable corrosion resistance, magnetic | Low to medium power ratings Up to high precision levels of quality |

| Non-Ferrous metals | ||

| Aluminium alloys | Light weight, non-corrosive and good machinability | Light duty instrument gears up to high precision quality |

| Brass alloys | Low cost, non-corrosive, excellent machinability | low cost commercial quality gears. Quality up to medium precision |

| Bronze alloys | Excellent machinability, low friction and good compatability with steel | For use with steel power gears. Quality up to high precision |

| Magnesium alloys | Light weight with poor corrosion resistance | Ligh weight low load gears. Quality up to medium precision |

| Nickel alloys | Low coefficient of thermal expansion. Poor machinability | Special gears for thermal applications to commercial quality |

| Titanium alloys | High strength, for low weight, good corrosion resistance | Special light weight high strength gears to medium precision |

| Di-cast alloys | Low cost with low precision and strength | High production, low quality gears to commercial quality |

| Sintered powder alloys | Low cost, low quality, moderate strength | High production, low quality to moderate commercial quality |

| Non metals | ||

| Acetal (Delrin | Wear resistant, low water absorbtion | Long life , low load bearings to commercial quality |

| Phenolic laminates | Low cost, low quality, moderate strength | High production, low quality to moderate commercial quality |

| Nylons | No lubrication, no lubricant, absorbs water | Long life at low loads to commercial quality |

| PTFE | Low friction and no lubrication | Special low friction gears to commercial quality |

Equations for basic gear relationships

It is acceptable to marginally modify these relationships e.g to modify the addendum /dedendum to

allow Centre Distance adjustments. Any changes modifications will affect the gear performance

in good and bad ways...

| Addendum | h a = m = 0.3183 p |

| Base Circle diameter | Db = d.cos α |

| Centre distance | a = ( d g + d p) / 2 |

| Circular pitch | p = m.π |

| Circular tooth thickness | ctt = p/2 |

| Dedendum | h f = h - a = 1,25m = 0,3979 p |

| Module | m = d /z |

| Number of teeth | z = d / m |

| Outside diameter | D o = (z + 2) x m |

| Pitch circle diameter | d = z . m ... (d g = gear & d p = pinion ) |

| Whole depth(min) | h = 2.25 . m |

| Top land width(min) | t o = 0,25 . m |

Module (m)

The module is the ratio of the pitch diameter to the number of teeth. The unit of the module

is milli-metres.Below is a diagram showing the relative size of teeth machined in a rack with module ranging

from module values of 0,5 mm to 6 mm

0,5 0,8 1

1,25

1,5 2,5 3

4 5 6

8 10 12

16 20 25

32 40 50

Normal Pressure angle α

An important variable affecting the geometry of the gear teeth is the normal pressure

angle. This is generally standardised at 20o. Other pressure

angles should be used only for special reasons and using considered judgment.

The following changes result from increasing the pressure angle

|

Gears required to have low noise levels have pressure angles 15o to17.5o

Contact Ratio

The gear design is such that when in mesh the rotating

gears have more than one gear

in contact and transferring the torque for some of the time. This

property is called

the contact ratio. This is a ratio of the length of the line-of-action

to the base pitch.

The higher the contact ratio the more the load is shared between

teeth. It is good practice to maintain a contact ratio of 1.2 or

greater.

Under no circumstances should the ratio drop below 1.1.

A contact ratio between 1 and 2 means that part of the time two pairs of teeth are in contact and during the remaining time one pair is in contact. A ratio between 2 and 3 means 2 or 3 pairs of teeth are always in contact. Such as high contact ratio generally is not obtained with external spur gears, but can be developed in the meshing of an internal and external spur gear pair or specially designed non-standard external spur gears.

A contact ratio between 1 and 2 means that part of the time two pairs of teeth are in contact and during the remaining time one pair is in contact. A ratio between 2 and 3 means 2 or 3 pairs of teeth are always in contact. Such as high contact ratio generally is not obtained with external spur gears, but can be developed in the meshing of an internal and external spur gear pair or specially designed non-standard external spur gears.

(Rgo2 - Rgb2 )1/2 + (Rpo2 - Rpb2 )1/2 - a sin α contact ratio m =p cos α

R go = D go / 2..Radius of Outside Dia of Gear

R gb = D gb / 2..Radius of Base Dia of Gear

R po = D po / 2..Radius of Outside Dia of Pinion

R pb = D pb / 2..Radius of Base Dia of Pinion

p = circular pitch.

a = ( d g+ d p )/2 = center distance.

R gb = D gb / 2..Radius of Base Dia of Gear

R po = D po / 2..Radius of Outside Dia of Pinion

R pb = D pb / 2..Radius of Base Dia of Pinion

p = circular pitch.

a = ( d g+ d p )/2 = center distance.

Spur gear Forces, torques, velocities & Powers

|

| Tangential force on gears F t = F cos α |

| Separating force on gears F s = F t tan α |

| Torque on driver gear T 1 = F t d 1 / 2 |

| Torque on driver gear T 2 = F t d 2 / 2 |

| Speed Ratio =ω 1 / ω 2 = d 2 / d 1 = z 2 /z 1 |

| Input Power P 1 = T1 .ω 1 |

| Output Power P 2 =η.T 1 .ω 2 |

Spur gear Strength and durability calculations

Designing spur gears is normally done in accordance with standards the two most

popular series are listed under standards above:

The notes below relate to approximate methods for estimating gear strengths. The methods are really only useful for first approximations and/or selection of stock gears (ref links below). — Detailed design of spur and helical gears is best completed using the standards. Books are available providing the necessary guidance. Software is also available making the process very easy. A very reasonably priced and easy to use package is included in the links below (Mitcalc.com)

The determination of the capacity of gears to transfer the required torque for the desired operating life is completed by determining the strength of the gear teeth in bending and also the durability i.e of the teeth ( resistance to wearing/bearing/scuffing loads ) .. The equations below are based on methods used by Buckingham..

The notes below relate to approximate methods for estimating gear strengths. The methods are really only useful for first approximations and/or selection of stock gears (ref links below). — Detailed design of spur and helical gears is best completed using the standards. Books are available providing the necessary guidance. Software is also available making the process very easy. A very reasonably priced and easy to use package is included in the links below (Mitcalc.com)

The determination of the capacity of gears to transfer the required torque for the desired operating life is completed by determining the strength of the gear teeth in bending and also the durability i.e of the teeth ( resistance to wearing/bearing/scuffing loads ) .. The equations below are based on methods used by Buckingham..

Bending

The basic bending stress for gear teeth is obtained by using the Lewis formula

σ = Ft / ( ba. m. Y )

- F t = Tangential force on tooth

- σ = Tooth Bending stress (MPa)

- b a = Face width (mm)

- Y = Lewis Form Factor

- m = Module (mm)

σ = Ft / ( ba. p. y )

Where y = Y/π and p = circular pitch

When a gear wheel is rotating the gear teeth come into contact with some degree

of impact. To allow for this a velocity factor ( Kv ) is introduced into the equation.

This is given by the Barth equation...

V = the pitch line velocity = d.ω/2 (m/s)

The Lewis formula is thus modified as follows

σ = K v.Ft / ( ba. m. Y )

To select gears from a stock gear catalogue or do a first approximation for a gear design select the gear material and obtain a safe working stress e.g Yield stress / Factor of Safety. /Safe fatigue stress

- Determine the input speed, output speed, ratio, torque to be transmitted

- Select materials for the gears (pinion is more highly loaded than gear)

- Determine safe working stresses (uts /factor of safety or yield stress/factor of safety or Fatigue strength / Factor of safety )

- Determine Allowable endurance Stress Se

- Select a module value and determine the resulting geometry of the gear

- Use the lewis formula and the endurance formula to establish the resulting face width

- If the gear proportions are reasonable then - proceed to more detailed evaluations

- If the resulting face width is excessive - change the module or material or both and start again

POWDER METALLURGY PROCESS

Overview

High quality gears can be made by Powder metallurgy method.Powder is pressed in dies to produce the tooth shape after which the product is sintered .This method is generally used for small gears .After the metallic powders have been produced and classified, the

conventional P/M process sequence

consists of three major steps: (1) blending and mixing of powders, (2) compaction, and (3) sintering, and a number of optional and finishing secondary operations.

Blending and mixing

Blending: mixing powder of the same chemical composition but different sizes

Mixing: combining powders of different chemistries

Blending and mixing are accomplished by mechanical means:

Except for powders, some other ingredients are usually added:

- Lubricants: to reduce the particles-die friction

- Binders: to achieve enough strength before sintering

- Deflocculants: to improve the flow characteristics during feeding

Compaction

Blended powers are pressed in dies under high pressure to form them into the required shape. The

work part after compaction is called a green compact or simply a green, the word green meaning not

yet fully processed.

Sintering

Compressed metal powder is heated in a controlled-atmosphere furnace to a temperature below its

melting point, but high enough to allow bounding of the particles:

The primary driving force for sintering is not the fusion of material, but formation and growth of bonds

between the particles, as illustrated in a series of sketches showing on a microscopic scale the changes

that occur during sintering of metallic powders.

Finishing operations

A number of secondary and finishing operations can be applied after sintering, some of them are:

- Sizing: cold pressing to improve dimensional accuracy

- Coining: cold pressing to press details into surface

- Impregnation: oil fills the pores of the part

- Infiltration: pores are filled with a molten metal

- Heat treating, plating, painting

Manufacturing Advantages of Powder Metallurgy:

- Cost Savings of up to 70% over other part manufacturing processes.

- Provides Close Dimensional Tolerances.

- Requires Minimal Machining.

- Results in Good Surface Finish.

- Excellent part to part reproducibility (Repetitive Accuracy).

- Often only process that produces parts with irregular curves, eccentrics, radial projections.

- Easily Produces parts requiring irregular holes, key-ways, flat sides, splines, or square holes.

- Easily Produces tapers and counter bores.

- Easily Produces slots, grooves, and bosses of varying depths.

- Axial projections possible but size depends on powder flowing into die recesses.

- Greater Customization Possible over other processes.

- Stronger Material Properties over plastics & dies casting.

- Greater Control of Material through sintering process, which is particularly important when working with stainless steel.

- Tailor material to be Ductile or Hard.

- Blend Materials to gain Desirable Material Properties.

- Corrosion Resistant.